EUREKA FAMILY

A400 - SEQUENTIAL | A450 - SIMULTANEOUSA400 – SEQUENTIAL

A450 – SIMULTANEOUS

TECHNICAL FEATURES

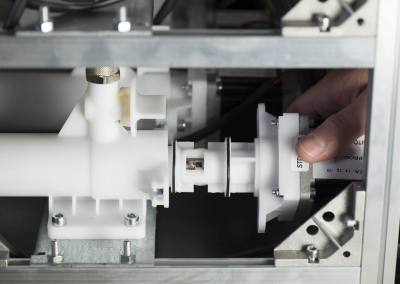

Automatic dosing system with patented progressive cavity pump (PCP) technology.

Suitable for a medium-sized point of sale, the Eureka is the most flexible automatic tinting machine in the market as it allows a sequential, simultaneous and gravimetric dosage (also in combined mode) of any type of pigment pastes, complying with the minimum dosing of 1/1000 fl. oz. (0.03 ml).

Pumps may be interchanged quickly and easily, doubling productivity for every single circuit through a replacement of a standard pump (0.3 L/min) with a hi-flow pump (0.6 L/min).

PLUS

- up to 8 circuits working simultaneously

- minimum dosing amount 1/1000 fl. oz. (0.03 ml)

- up to 32 canisters

- canisters capacity: 3L – 5L

- recalibration NOT necessary

- easy-to-refill canisters

- easy to maintain

- each circuit can be customized with HF high flow pumps (0.7 L/min)

- automatic elevator

- dosing samples available

TECHNICAL FEATURES

|

Suitable for |

Water, universal and solvent based colorants |

|

Dosing system |

Volumetric Sequential (A400) Volumetric Simultaneus (A450) (up to 8 circuits) Gravimetric Sequential (A400) Gravimetric Combined (A450) (up to 8 circuits) |

|

Number of circuits |

Up to 32 |

|

Dosing principle |

Progressive Cavity Pump (PCP) |

|

Canisters capacity |

3-5 Litres |

|

Pump capacity |

STD pumps: 0,3 l/min |

|

Average precision |

+/-1% (data influenced by the viscosity of the colourants) |

|

Minimum dosing quantity |

1/1000 fl. oz. (0,03 ml) (data influenced by the viscosity of the colourants) |

|

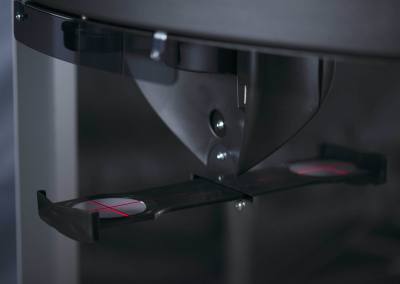

Nozzles closing system |

Automatic watertight humidifier cap |

|

Can presence |

Photocell |

|

Can positioning |

Automatic elevator |

|

Minimum can height |

90 mm |

|

Maximum can height |

565 mm |

|

Elevator vertical movement |

300 mm |

|

Maximum dimensions |

W 950 x D 750 x H 1.150 mm (16 canisters version) W 1320 x D 750 x H 1.150 mm (24 canisters version) W 1320 x D 850 x H 1.150 mm (32 canisters version) |

|

Weight |

180 kg (16 canisters version) 250 kg (24 canisters version) 300 kg (32 canisters version) |

|

Power supply |

230/115 V AC 50/60 Hz |